YCS Offshore Hydraulic Piling Hammers

Classification:

Product accessories:

- 产品描述

- 参数性能

- 应用领域

- 客户现场

-

- Commodity name: YCS Offshore Hydraulic Piling Hammers

★ Land and water hydraulic piling hammers (except for the 05 series) adopt patented ram technology, which facilitates customers to make the most reasonable choice of hammer head quality between different geology and piles; ★ Customers can obtain hydraulic pile hammers of different tonnage levels through the combination of different quality hammers. ★ From a cost-effectiveness perspective, the use of combined hammer technology for CFM hammers is an extremely economical choice; ★ The combination ram can prolong the duration of the impact force, effectively penetrate with high energy, and effectively protect the precast concrete pile head.

CFM hydraulic pile hammer is the result of the hydraulic hammer designing, using and manufacturing experience for more than ten years. It is with simple design and fine design, and the striking energy can be adjustable according to foundation condition and pile depth. Pile in the same foundation condition can be program group pile copied by the trailing pile.

CFM hydraulic pile hammer is the result of the hydraulic hammer designing, using and manufacturing experience for more than ten years. It is with simple design and fine design, and the striking energy can be adjustable according to foundation condition and pile depth. Pile in the same foundation condition can be program group pile copied by the trailing pile.

Besides that, the cap can be designed according to the customer requirement, to be suitable for each kinds and specifications of concrete pile, steel tube pile and steel plate pile. CFM can supply each kinds of hydraulic pile hammer, from 60kJ to infinity. Simple reliable design, find manufacturing and fast service can make sure the pile hammer give full play.

The off shore pile hammer is mainly for sea industry off shore foundation construction. Its working area can be big sea industry foundation construction, such as oil and gas platform on sea, big bridge, tube installation, deep water structure and wind power on sea and so on. It is mainly for each kinds and specifications steel pile and prefabricated pile.Comparison to onshore hydraulic pile hammer:

● Off shore hydraulic pile hammer uses pressurized fully closed hammer body design (patent) and submarine design to make sure the hydraulic driving system, control system, striking system can be work normally under deep water and to improve its transferring efficiency.

● Special designing cap water level control system can make sure the pile hammer can work without touching water under deep water to improve its transferring efficiency much.

● Special hammer cylinder pressure control system can realize automatic control the pressure in the close hammer body.

● Forged and heated ram with long axle, and close automatic lubrication system can make sure hammer striking system work with high reliability.

● Special antiseptic and ooze proof designing can make sure hammer work for long time.

● This off shore pile hammer can be suitable for deep water working. Besides hammer body and hydraulic station, there will be with another auxiliary devices, such as winch for tube line and control maintenance station. -

1. Key Technologies and Characteristics

● Pressurize fully close hammer body (patent) make sure it can work with high reliability in very bad outside environment, especially the deep water working.

● High integrated hydraulic driving system can make sure it work with high efficiency, energy saving, environment friendly and high reliability.

● Automatic close technology for high pressure pipeline if pressure losing, is to avoid oil leakage during unusual knocking.

● Oil drain technology for pipeline can make sure the oil drain out when shifting to other place, to avoid oil leakage and pollution.

● Modern program control technology can realize normal and automatic control for striking energy and frequency in the same foundation condition. The striking energy can be willfully preset in the rated range.

● Fine sensor technology, remote technology and man-machine interface can automatic monitor the pressure, temperature, position and its condition, to realize pile hammer numerical control and malfunction automatic diagnosing and displaying.

● It can be guiding pile or free lifting pile.2. Main Technical Parameter

Structural parameters

1010

2020A

3030

4040

6050

6060

8075

8090

type

unit

YCS180

YCS450

YCS700

YCS1000

YCS1250

YCS1500

YCS1800

YCS2100

Nominal energy

kJ

180

450

700

1000

1250

1500

1800

2100

Min. striking Stroke

mm

200

Max. striking Stroke

mm

1200

1500

1800

ram weight

t

10

20

30

40

50

60

75

90

total weight without cap

t

20

40

55

75

90

110

135

160

Max. Strike frequency

min-1

25~70

25~60

Working Pressure

MPa

25~28

Working flow

L/Min

250

500

750

1000

1500

2000

3000

4000

Main motor power

Kw

132

264

396

528

800

1050

1600

2100

Cap weight

Kg

500

1000

2000

2000

3000

5000

8000

13000

-

Anchor point positioning: text animation displacement to the corresponding position after adding anchor point links

Product Description

CFM hydraulic pile hammer is the result of the hydraulic hammer designing, using and manufacturing experience for more than ten years. It is with simple design and fine design, and the striking energy can be adjustable according to foundation condition and pile depth. Pile in the same foundation condition can be program group pile copied by the trailing pile.

CFM hydraulic pile hammer is the result of the hydraulic hammer designing, using and manufacturing experience for more than ten years. It is with simple design and fine design, and the striking energy can be adjustable according to foundation condition and pile depth. Pile in the same foundation condition can be program group pile copied by the trailing pile.

Besides that, the cap can be designed according to the customer requirement, to be suitable for each kinds and specifications of concrete pile, steel tube pile and steel plate pile. CFM can supply each kinds of hydraulic pile hammer, from 60kJ to infinity. Simple reliable design, find manufacturing and fast service can make sure the pile hammer give full play.

The off shore pile hammer is mainly for sea industry off shore foundation construction. Its working area can be big sea industry foundation construction, such as oil and gas platform on sea, big bridge, tube installation, deep water structure and wind power on sea and so on. It is mainly for each kinds and specifications steel pile and prefabricated pile.

Comparison to onshore hydraulic pile hammer:

● Off shore hydraulic pile hammer uses pressurized fully closed hammer body design (patent) and submarine design to make sure the hydraulic driving system, control system, striking system can be work normally under deep water and to improve its transferring efficiency.

● Special designing cap water level control system can make sure the pile hammer can work without touching water under deep water to improve its transferring efficiency much.

● Special hammer cylinder pressure control system can realize automatic control the pressure in the close hammer body.

● Forged and heated ram with long axle, and close automatic lubrication system can make sure hammer striking system work with high reliability.

● Special antiseptic and ooze proof designing can make sure hammer work for long time.

● This off shore pile hammer can be suitable for deep water working. Besides hammer body and hydraulic station, there will be with another auxiliary devices, such as winch for tube line and control maintenance station.

Parameter Performance

1. Key Technologies and Characteristics

● Pressurize fully close hammer body (patent) make sure it can work with high reliability in very bad outside environment, especially the deep water working.

● High integrated hydraulic driving system can make sure it work with high efficiency, energy saving, environment friendly and high reliability.

● Automatic close technology for high pressure pipeline if pressure losing, is to avoid oil leakage during unusual knocking.

● Oil drain technology for pipeline can make sure the oil drain out when shifting to other place, to avoid oil leakage and pollution.

● Modern program control technology can realize normal and automatic control for striking energy and frequency in the same foundation condition. The striking energy can be willfully preset in the rated range.

● Fine sensor technology, remote technology and man-machine interface can automatic monitor the pressure, temperature, position and its condition, to realize pile hammer numerical control and malfunction automatic diagnosing and displaying.

● It can be guiding pile or free lifting pile.

2. Main Technical Parameter

Structural parameters | 1010 | 2020A | 3030 | 4040 | 6050 | 6060 | 8075 | 8090 | |

type | unit | YCS180 | YCS450 | YCS700 | YCS1000 | YCS1250 | YCS1500 | YCS1800 | YCS2100 |

Nominal energy | kJ | 180 | 450 | 700 | 1000 | 1250 | 1500 | 1800 | 2100 |

Min. striking Stroke | mm | 200 | |||||||

Max. striking Stroke | mm | 1200 | 1500 | 1800 | |||||

ram weight | t | 10 | 20 | 30 | 40 | 50 | 60 | 75 | 90 |

total weight without cap | t | 20 | 40 | 55 | 75 | 90 | 110 | 135 | 160 |

Max. Strike frequency | min-1 | 25~70 | 25~60 | ||||||

Working Pressure | MPa | 25~28 | |||||||

Working flow | L/Min | 250 | 500 | 750 | 1000 | 1500 | 2000 | 3000 | 4000 |

Main motor power | Kw | 132 | 264 | 396 | 528 | 800 | 1050 | 1600 | 2100 |

Cap weight | Kg | 500 | 1000 | 2000 | 2000 | 3000 | 5000 | 8000 | 13000 |

Application Areas

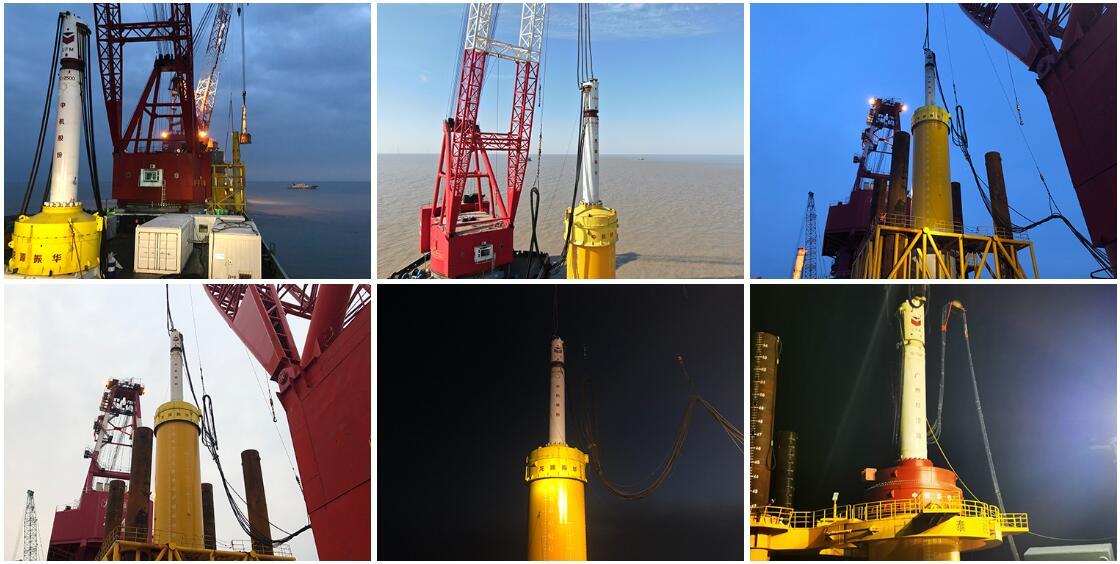

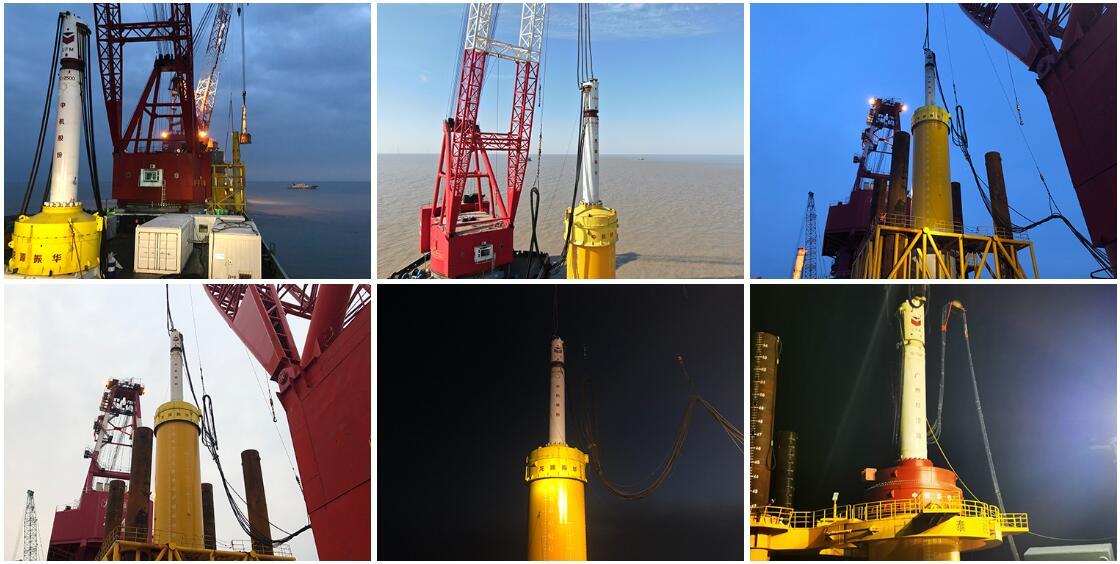

Customer Site

Feel free to contact us for expert help

Product brochures and more are available for download!

We will contact you within one working day. Please pay attention to your email.