Accelerate the development of new quality productivity · front-line research|"Nail" more than 100-meter-long steel piles into the 2,500-meter deep seabed, Nantong makes "super hammer" to make the offshore platform "stand"

16

-

05

-

2024

On April 11, a reporter from Xinhua Daily · Junction walked into CFM worshp in Hai'an, and saw an ultra-deepwater piling hammer standing in front of him, five or six stories high. "This 'behemoth' completed sea trials in the South China Sea last year and is about to enter engineering application." Zhang Changlong, vice chairman of the company, introduced that the company developed China's first 2500-meter ultra-deepwater hydraulic piling hammer, which filled the gap in the core equipment and piling technology of piling in the ultra-deepwater environment in China, and boosted China's underwater piling operation capacity from shallow water to ultra-deep water.

To develop offshore wind power, equipment should come first. Under the frequent impact of typhoons and waves, offshore wind power platforms must lay steel piles on the seabed in order to "stand on their feet". However, for a long time, the R&D and manufacturing technology of ultra-large hydraulic piling hammer, the key equipment for offshore platform "foundation", has been in the hands of a few foreign manufacturers. "In the past, marine hydraulic piling hammers were completely dependent on imports, especially ultra-deep water hydraulic piling hammers were only rented but not sold, and the construction needed to wait for the gap period of the equipment, sometimes even for nearly a year, which seriously affected the progress of the project." Zhang Changlong told Xinhua Daily · Junction reporter.

In order to completely solve this problem, with the support of the parent company CAM and BRIMET, after nearly 3 years of scientific research, CFM has developed a hydraulic piling hammer product with completely independent property rights. Its price is only 70% of similar foreign products, and it is easy to maintain and relatively simple to operate.

Committed to the development of high-end marine equipment, CFM successfully developed China's first 2500 kJ large hydraulic pile hammer in 2018, which was officially installed at the end of 2019. In 2021, the first domestically produced YC-3500 kJ double-acting fully hydraulic piling hammer was delivered to the Guangzhou Salvage Bureau Huatianlong Ship Equipment for use, and nearly 100 steel piles have been laid in the South China Sea so far.

The "bulky" body of the ultra-deep water hydraulic piling hammer weighing about 165 tons contains "high-precision" technology. Chen Taiqing, deputy chief engineer of the company, pointed to the upper part of the piling hammer and introduced that this is the driving system of the entire component, using tubeless system integration technology to integrate the core components such as working cylinders, piston rods, accumulators and blow valves.

Forging "super hammers", piling hammer parts structure must have high reliability. Xinhua Daily · Junction reporter saw in the workshop that the middle cylinder adopts a double-layer structure, and the ram is forged as a single piece. "Each 'blow' is equivalent to the force generated by a car hitting at a speed of 100 kilometers per hour." Chen Taiqing introduced that during piling, hydraulic power transmission was used to drive the ram weighing 33 tons to reciprocate up and down, and a steel pile more than 100 meters long was driven into the 2,500-meter deep sea bed.

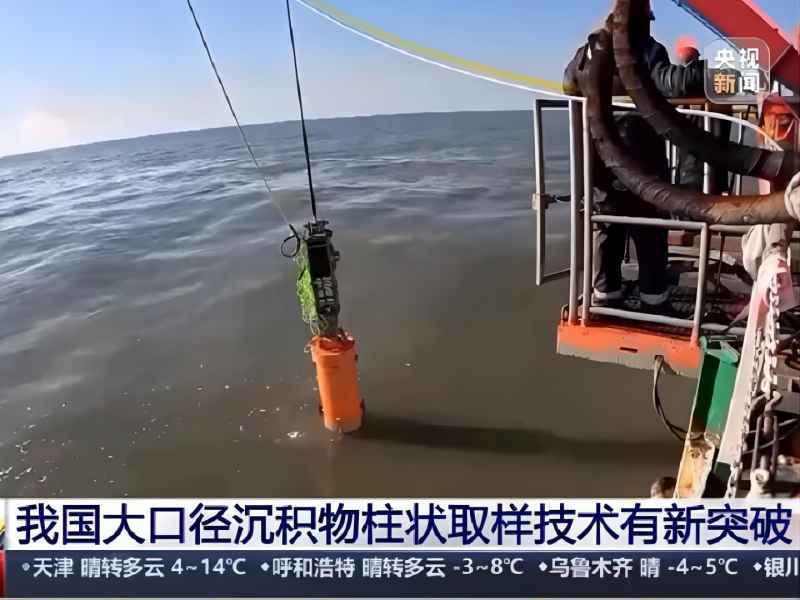

In the field of deep-sea scientific research, CFM is also "gearing up". In March, the Institute of Oceanology of the Chinese Academy of Sciences developed a large-diameter sediment columnar sampling system, carried a scientific research vessel to complete the sea test verification in the South Yellow Sea, and obtained samples of the continental strata in the low sea level period since the last glacial maximum. The "reciprocating ramming" part of the sampling system adopts a 3,500-meter deep-water sampling ramming hammer developed and manufactured by CFM, which is also another major breakthrough in the field of underwater hydraulics of the company.

The sampling diameter of the traditional columnar sediment sampler is mostly about 110 mm, but according to the needs of scientific research, it is necessary to develop a 500 mm large-diameter sediment sampling system, which brings many problems such as difficulty in connecting the sampling tube, small penetration depth, easy falling off of the sample in the tube, and difficulty in hoisting. The R&D team of more than 20 people in the machine forging changed the original single rod connection to double rod connection, adopted a hollow structure, reduced friction, achieved a breakthrough in the sampling length, and applied for the patent of "a hollow ramming hammer and operation method for submarine structure sampling and detection".

At present, the maximum striking energy of the piling hammer used in the construction of shallow sea areas is only 4000 kJ on a global scale. Since last year, CFM has fully participated in the research and development of ultra-large hydraulic piling hammer projects of more than 6,000 kJ, and the breakthrough of this core equipment will promote China offshore wind power to achieve the world's first system in this field and the world's leader.

CFM takes technological innovation as the "lifeline" of development, strengthens the application and transformation of scientific and technological achievements, continuously breaks through technical barriers in the field of hydraulic hammers, and has won the first prize of provincial scientific and technological progress for many times, and the products have been identified as provincial high-tech products. To promote the "big country heavy weapon" to the "new", Zhang Changlong said that the company will continue to serve the needs of the country, focus on the main business to create a source of original technology and a "new highland" of scientific and technological innovation, and continue to provide strong support for the high-quality development of major equipment in China's offshore field.

Share:

Related News